Choosing the right Clutch featuring XCLUTCH!!

|

|

Time to read 7 min

|

|

Time to read 7 min

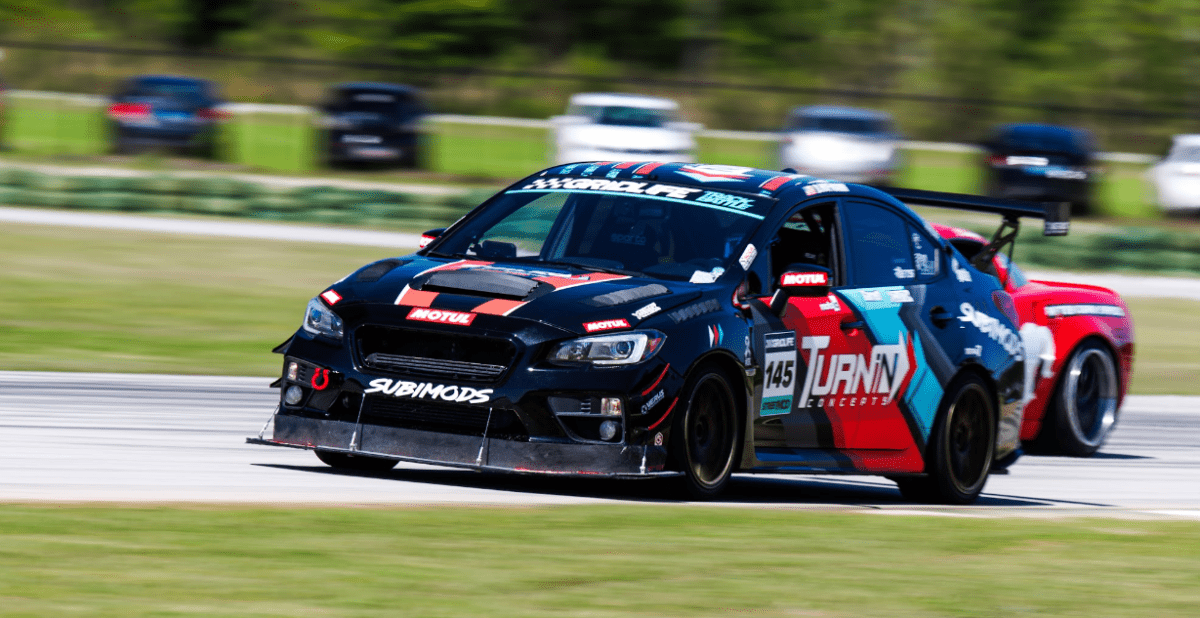

In the middle of racing towards the corkscrew at Laguna, as I upshifted to climb up the hill, I could hear the RPMs go up but, felt no additional power. I looked at the dash to confirm I was in the right gear and that's when I knew it finally happened, after 2+ years of racing on 660whp and being loaded on and off the trailer the clutch had finally started to quit on me. I was pretty happy with the timing as it didn't owe me anything as far as I was concerned and part of me was just really glad it wasn't a money shift.

Clutches are consumables when it comes to racing and I get asked often of how long should they last, how can I tell if my clutch is bad by looking at it, etc. So I decided who better to ask than the source its self, Steve from XCLUTCH, to help clear up some of the common questions and misconceptions.

As we review my 9in Twin Sprung Organic Clutch, keep in mind that when choosing a clutch it's important to be sure your power level and application is being considered. If you're ever unsure of which clutch is the right fit for you, the representatives at XCLUTCH are always willing to help.

So back to my slipped clutch review - a slipped clutch is when the disc is worn down to a point where the pressure plate isn't able to exert enough clamp load allow the clutch to operate properly and when the clutch is engaged the only thing accelerating is the heat in the discs. You may notice on a slipped clutch once you generate some heat (like racing on a race track heat) the slipping will be present. You may also notice that when the clutch is cooled down a bit you're able to street drive relatively normal. In my case, this happened due to too much wear on the discs. There's a service limit to how much wear the discs can have before the pressure plate is unable to do it’s job, which is to provide clamping force on the discs and against the flywheel so it can transfer the engine torque to the transmission.

To break it down a bit further the pressure plate design that I have is a diaphragm type which is very common due to reasons such as, their spring having the ability to be less effected by centrifugal forces ( engine RPM), smoother engagement resulting in better control /less wear and easier drivability. Another benefit of the diaphragm type is the way the pressure is distributed uniformly to ensure proper contact with the clutch disc , meaning the plates will wear evenly and lost longer. Diaphragm types uses a spring, or what's called the diaphragm spring, to apply the clamping force on to the pressure ring ,which is the circular plate of ductile iron that will then push the discs against the flywheel. When looking at the pressure plate assembly, you might also see some thin flexible metal strips - these are called the drive straps and they are responsible for transferring the engine torque from the pressure ring to the clutch cover as well as helping the pressure ring to be able to retract during disengagement.

Focusing back in on my well used pressure plate - we can see that there are a lot of spots that are called heat checking. This is caused due to the organic material the discs are made out of as well as the movement of the marcel spring. The marcel spring is the thin wave-washer spring that is in the middle of the disc lining. The marcel spring is what helps eliminate clutch chatter and provides a smooth "cushioned" shift allowing for easier clutch engagement. After some time the marcel spring does flatten out a bit making it so there is no cushion between the linings. This means the friction disc will grip harder on the pressure plate during engagement more instantly causing the effect of the heat checking spots. When there is a lot of cushion the engagement between the disc and pressure plate is smoothed out in the final stage of the clamping action, which wouldn’t be visible on the pressure plate unlike the heat spots that are very visible. These heat checking spots are considered normal wear for a twin organic like mine.

We can also see on the pressure plate where the clutch was slipping which looks very different compared to heat checking, it looks more like a smear than just spots. This again is because of the friction coefficient of the two surfaces sliding across each other is below the optimal service life. The friction coefficient declines over time due to things such as the contact pressure, temperature from the sliding, speed of the sliding and the surface roughness. Looking at the facings of the upper and lower discs we can see there is a glazing on it from the heat deteriorating the facings. The Heat is produced due to the mechanical work happening by the frictional forces. These glazed areas are a visual representation of the areas that have a reduced coefficient of friction and directly correlate to the glazing marks on the pressure plate.

Upon further examination of the friction discs, we noticed the damper springs were also showing signs of wear based on them having some movement to them. This is super common to see the springs be worn after being used a while, since they are constantly back and forth from going one way when on throttle and the opposite way when in deceleration. The springs job is to work as a torsional vibration damper, absorbing the fluctuations of the engine rpm as well as to allow the power delivery to be smooth and linear. After heavy use of the clutch it's not recommended to just replace the worn discs in due to the tolerance stack up and taper wear. It's noted that the pressure face and intermediate plate have a taper wear that are not to be machined unlike the flywheel. If only new discs are being replaced it will create an uneven wear and partial contact leaving the life of your clutch shortened significantly

The intermediate or floater plate is also telling the same story as the pressure plate. We see the heat checking from regular clutch engagement and the heat discoloration from the slipping. The role of the intermediate plate is to ensure each disc on either side can grip uniformly without jolting. The intermediate or floater plate "floats" when the clutch pressure is released and this the rattling sound you hear when the clutch pedal is down.

Next we examined the release bearing and we noticed the ears were bent out a bit which can happen during installation of the fork. There was also a slight tear on the ear from being removed and reinstalled multiples times and it would have failed if we let it go too long. The release bearing may be small but it's job is very big. When engaging the clutch pedal, a release fork pushes the release bearing into the diaphragm spring and as it's rotating - it's job is to absorb the rotational motion of the spring and the linear motion of the release fork. The goal is to reduce wear between the rotating and non-rotating components. So it's important if you see a release bearing that has the ears bent or some wear and tear on it, just spend the $40-60 to replace it for peace of mind. When buying XCLUTCH service kits they actually have a new release bearing that comes in the kit for this reason.

Last we examined the chromoly flywheel and it did have some taper to it but, after measuring it the flywheel was still in good shape to be re machined if we wanted to go that route. The flywheel is responsible for three jobs, the first one is to maintain the rotational inertia that assists in keeping the engine rotating and provides steady distribution of the torque. The second job is for the ring gear on the outer diameter of the fly wheel to provide the starter motor to engage engine rotation and the third as we well know by now is to act as a driving fiction surface for the discs.

So to recap - my XCLUTCH 9in Twin Sprung Organic Clutch was slipping due to the wear on the friction dics after 2+ years of abuse at 660whp. We reviewed what each of the components of the clutch does and the wear from racing abuse that showed up on them. As a reminder it's important to take away that the only part of the clutch that should be considered to be remachined is the flywheel, the rest of the components of the clutch all develop a taper and should be replaced. Machining the pressure plate, discs or intermediate plate is not recommended due to how the stack up would end up creating uneven wear and early end of service life to the clutch. In the next article I'm going to cover more about why I chose XCLUTCH, the install process and what separates them from the other clutch companies as well as some Q&A I've received from the subie community.

All Photo Credit Goes To The Respected Owners!